NexDroid-Robot

Industrial Robot Introduction

Generally, an industrial robot consists of three main components and six subsystems.

The three main components are the mechanical part, the sensing part, and the control part.

The six subsystems include the mechanical structure system, the drive system, the perception system, the robot-environment interaction system, the human-robot interaction system, and the control system.

Mechanical Structure System

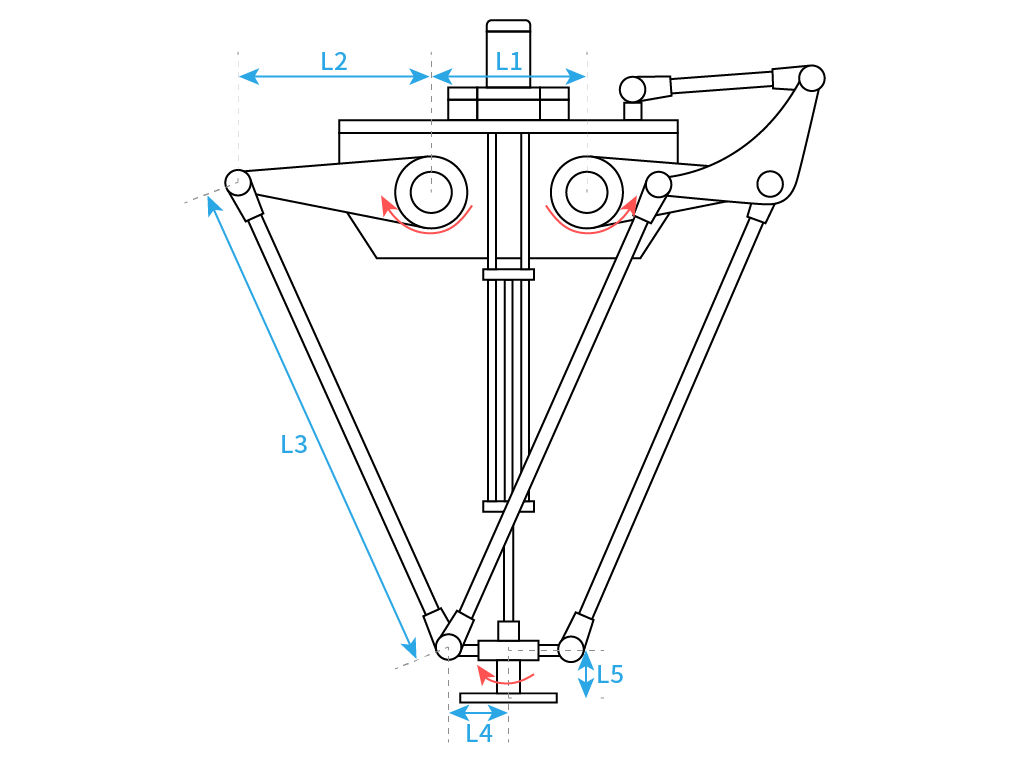

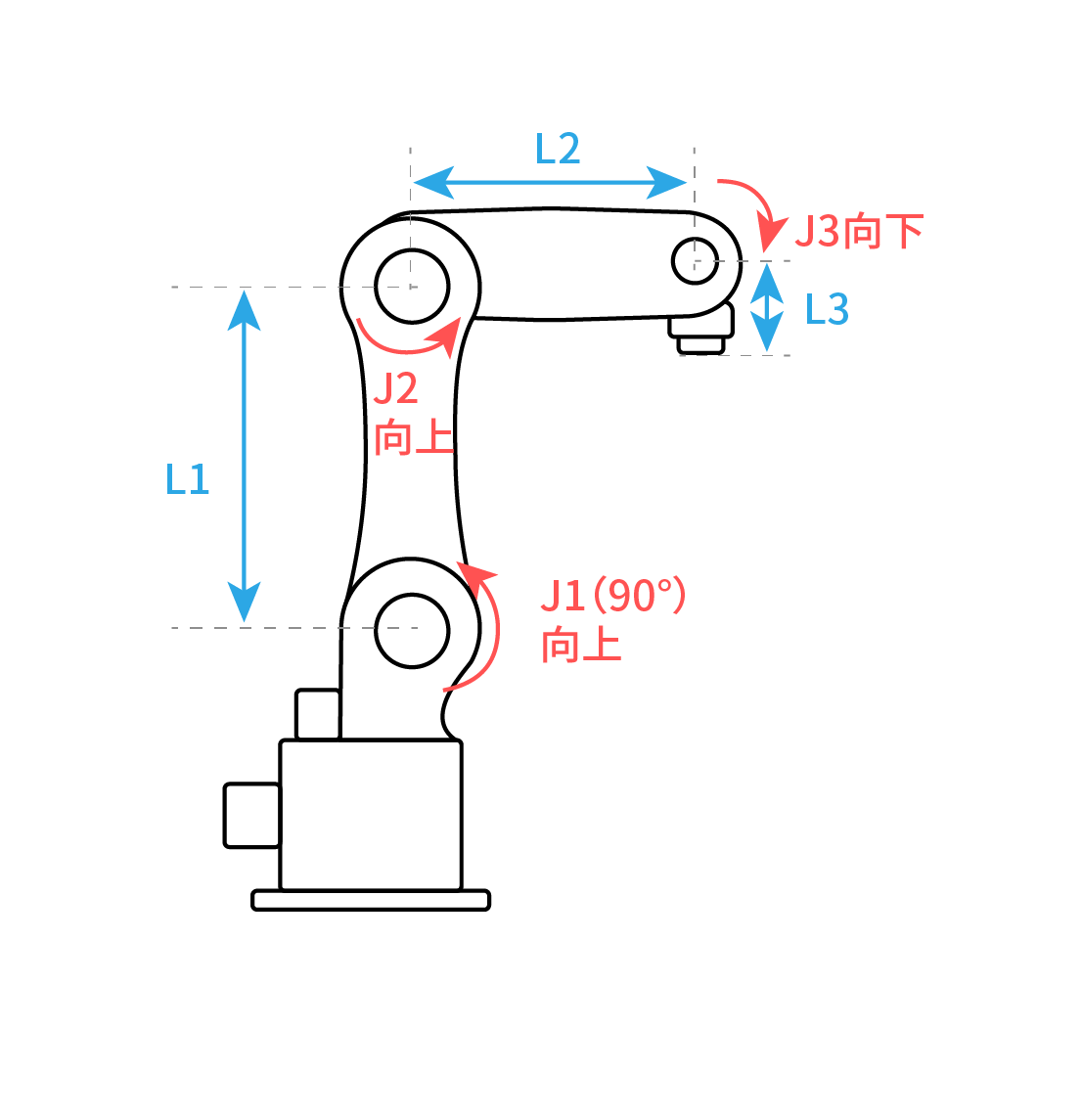

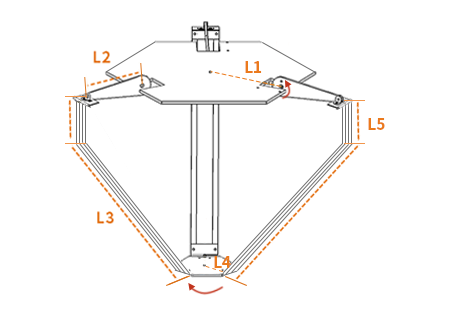

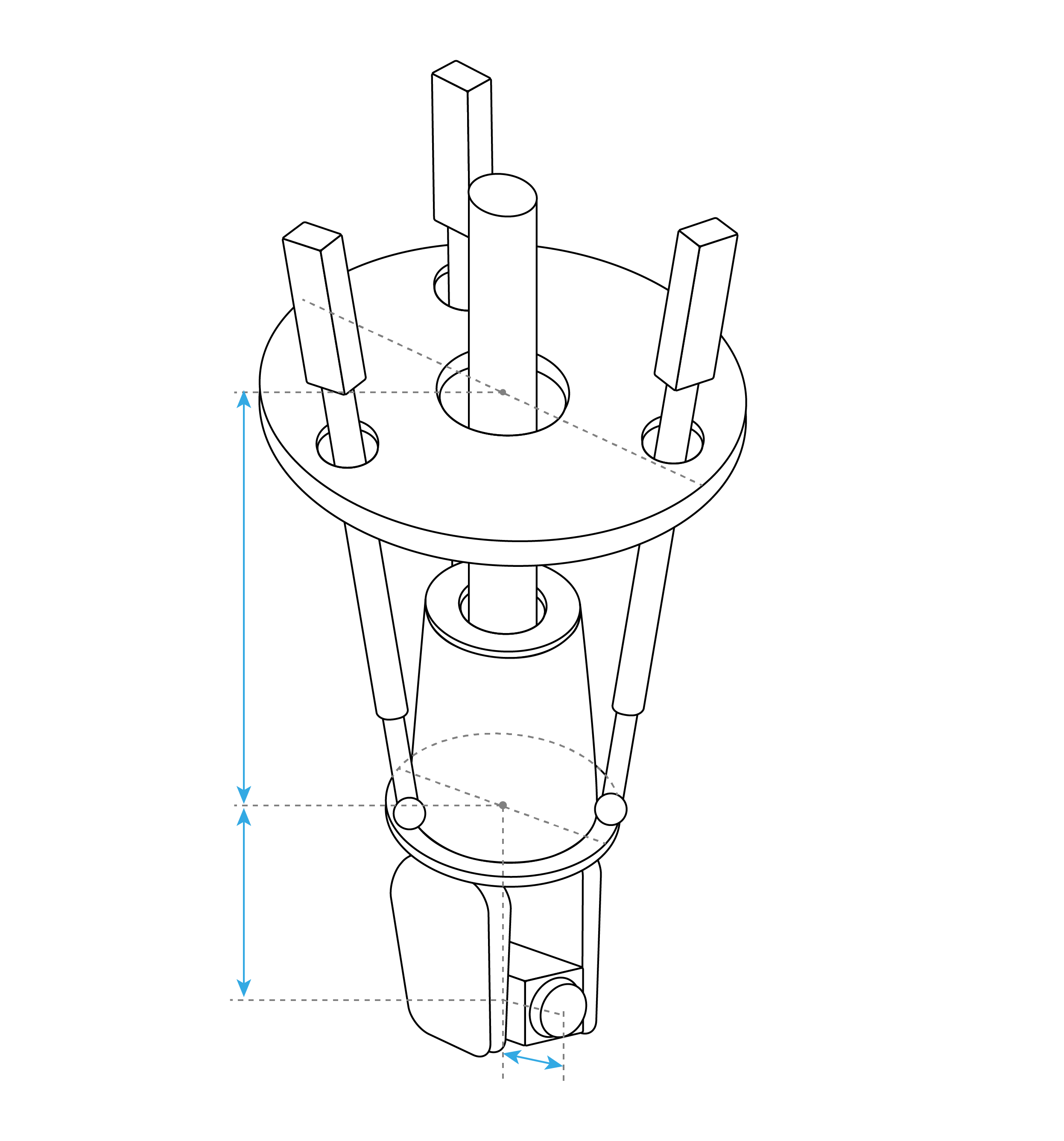

From the perspective of mechanical structure, industrial robots are generally divided into serial robots and parallel robots. The characteristic of a serial robot is that the movement of one axis changes the coordinate origin of another axis, whereas in a parallel robot, the movement of one axis does not change the coordinate origin of another axis. Early industrial robots all adopted serial mechanisms. A parallel mechanism is defined as a closed-loop mechanism where the moving platform and the fixed platform are connected through at least two independent kinematic chains, the mechanism has two or more degrees of freedom, and is driven in a parallel manner. A parallel mechanism has two components: the wrist and the arm. The working area of the arm has a significant impact on the workspace, while the wrist is the connecting part between the tool and the main body. Compared with serial robots, parallel robots have the advantages of high rigidity, stable structure, large load capacity, high micro-motion precision, and low motion load. In terms of position solution, the forward kinematics of serial robots are easy, but the inverse kinematics are very difficult; for parallel robots, it is the opposite, with difficult forward kinematics but very easy inverse kinematics.

Drive System

The drive system is the apparatus that provides power to the mechanical structure system. Depending on the power source, the transmission methods of the drive system are divided into four types: hydraulic, pneumatic, electric, and mechanical. Early industrial robots used hydraulic drives. Due to issues such as leakage, noise, and instability at low speeds in hydraulic systems, as well as the bulky and expensive power units, currently, hydraulic-driven industrial robots are only used in large heavy-duty robots, parallel processing robots, and some special applications. Pneumatic drives have the advantages of fast speed, simple system structure, easy maintenance, and low cost. However, pneumatic devices operate at low pressures and are not easy to position precisely, so they are generally only used for driving the end effectors of industrial robots. Pneumatic grippers, rotary cylinders, and pneumatic suction cups, as end effectors, can be used for grasping and assembling workpieces with medium and small loads. Electric drive is currently the most widely used type of drive. Its characteristics include convenient power supply, fast response, strong driving force, easy signal detection, transmission, and processing, and it can adopt a variety of flexible control methods. The drive motors generally use stepper motors or servo motors, and currently, direct drive motors are also used, but they are more expensive and the control is more complex. The reducers matched with the motors generally use harmonic drives, cycloidal pinwheel reducers, or planetary gear reducers. Due to the large demand for linear drives in parallel robots, linear motors have been widely used in the field of parallel robots.

Perception System

The robot perception system transforms various internal state information and environmental information of the robot from signals into data and information that the robot itself or other robots can understand and utilize. In addition to perceiving mechanical quantities related to its own working status, such as displacement, speed, and force, visual perception technology is an important aspect of industrial robot perception. The visual servo system uses visual information as a feedback signal to control and adjust the position and posture of the robot. Machine vision systems are also widely used in quality inspection, workpiece identification, food sorting, and packaging. The perception system consists of internal sensor modules and external sensor modules. The use of intelligent sensors enhances the robot's mobility, adaptability, and intelligence level.

Robot-Environment Interaction System

The robot-environment interaction system is a system that enables the robot to connect and coordinate with devices in the external environment. The robot and external devices are integrated into a functional unit, such as a machining and manufacturing unit, welding unit, assembly unit, etc. Of course, multiple robots can also be integrated into a functional unit to execute complex tasks.

Human-Robot Interaction System

The human-robot interaction system is a device for humans to connect with and participate in the control of robots. For example: computer standard terminals, instruction control consoles, information display boards, hazard signal alarms, etc.

Control System

The task of the control system is to control the robot's actuators to complete the specified movements and functions based on the robot's operation instructions and the signals fed back from the sensors. If the robot does not have the characteristic of information feedback, it is an open-loop control system; if it has the characteristic of information feedback, it is a closed-loop control system. According to the control principle, it can be divided into program control systems, adaptive control systems, and artificial intelligence control systems. According to the form of motion control, it can be divided into point-to-point control and continuous path control.

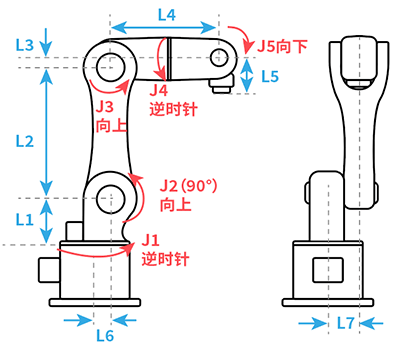

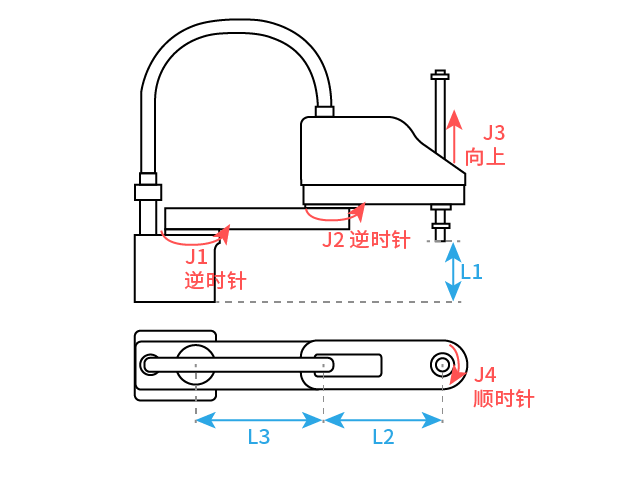

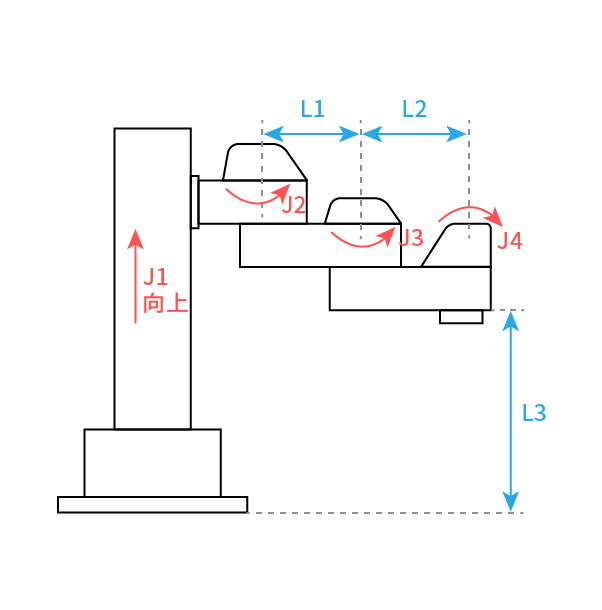

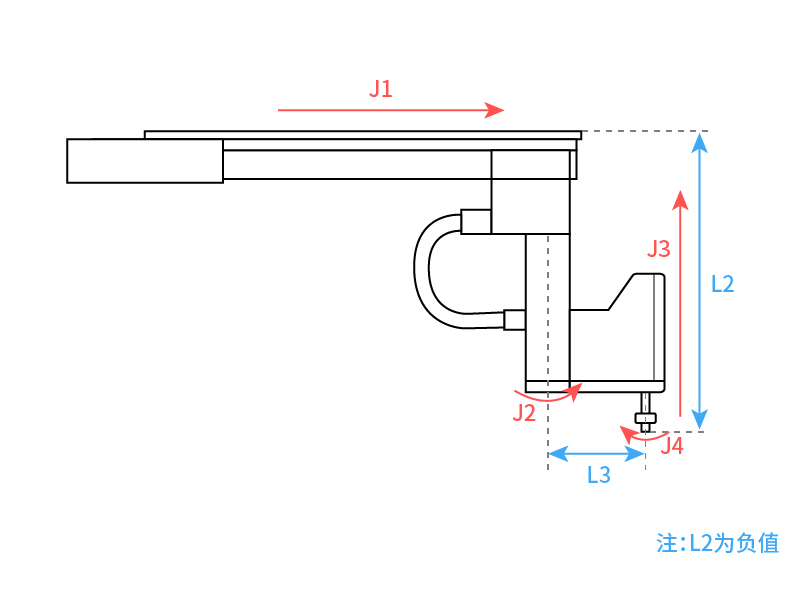

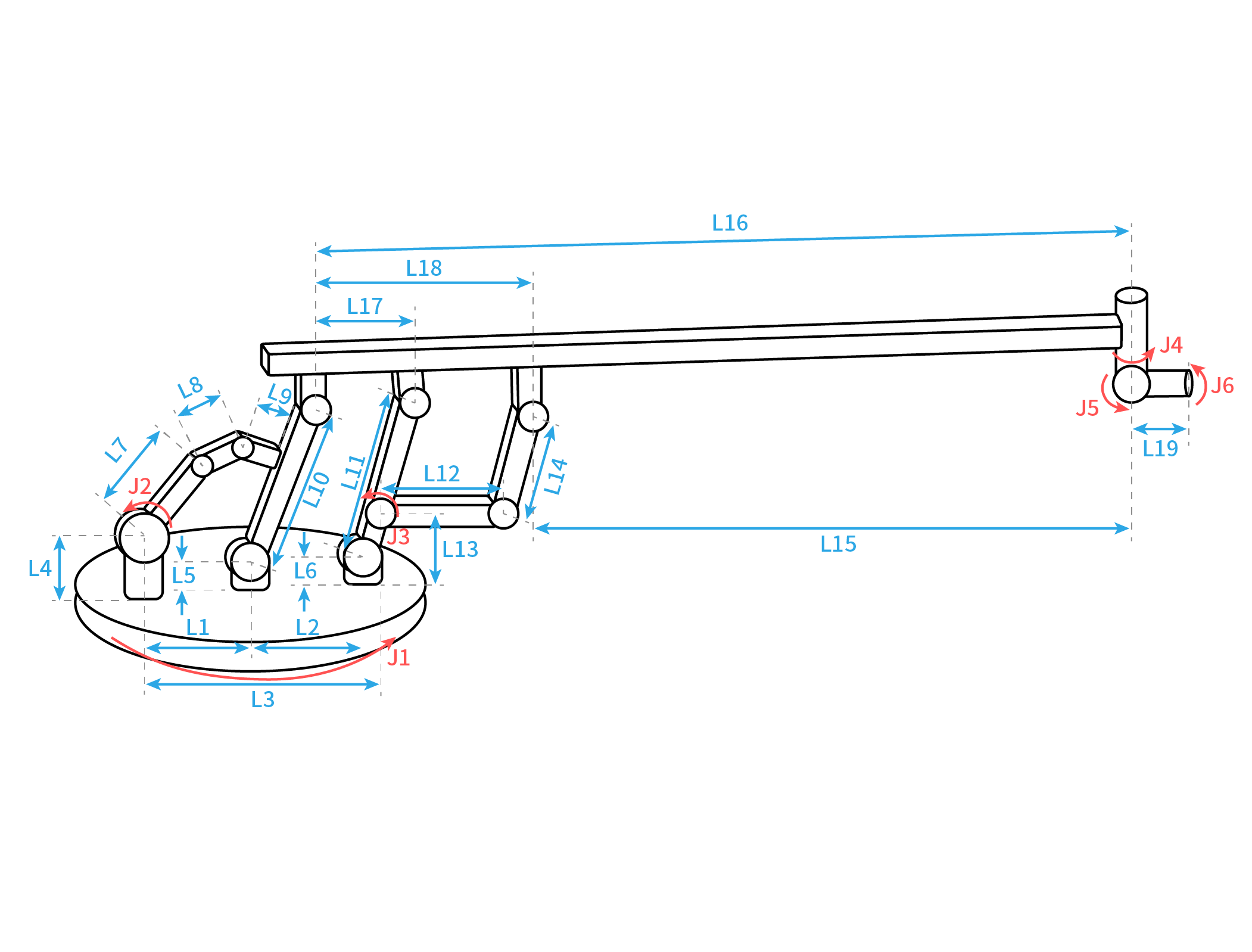

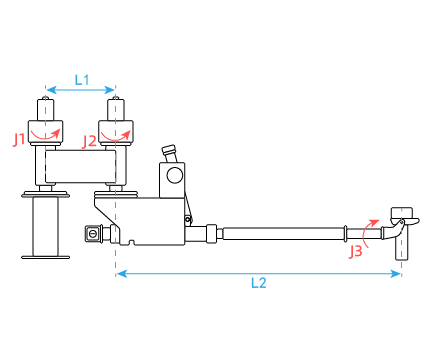

Types of Robots Supported by NexDroid

The NexDroid control system can support the following types of robots, including but not limited to those listed.

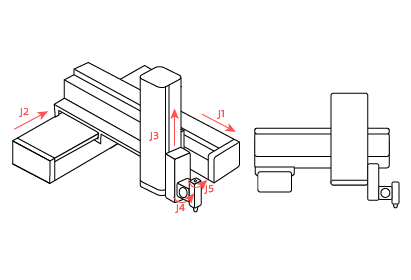

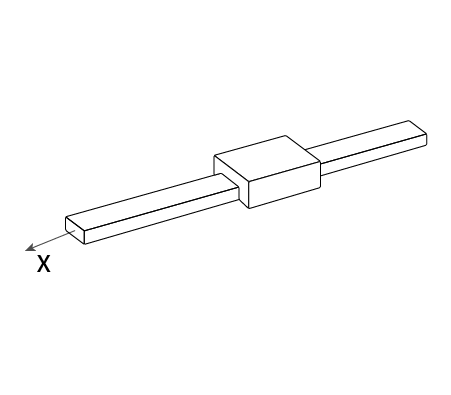

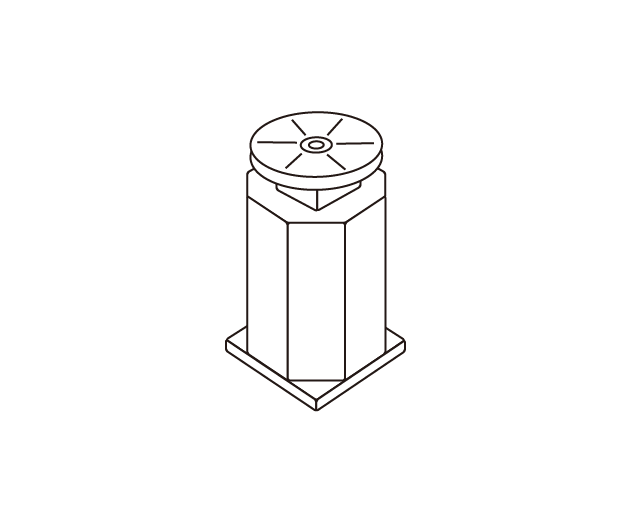

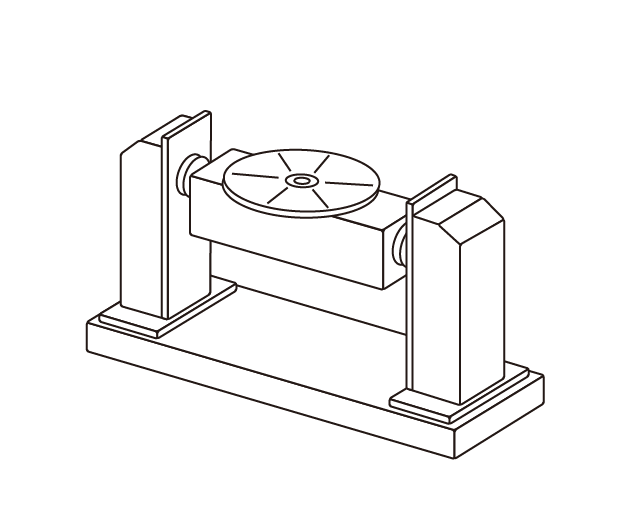

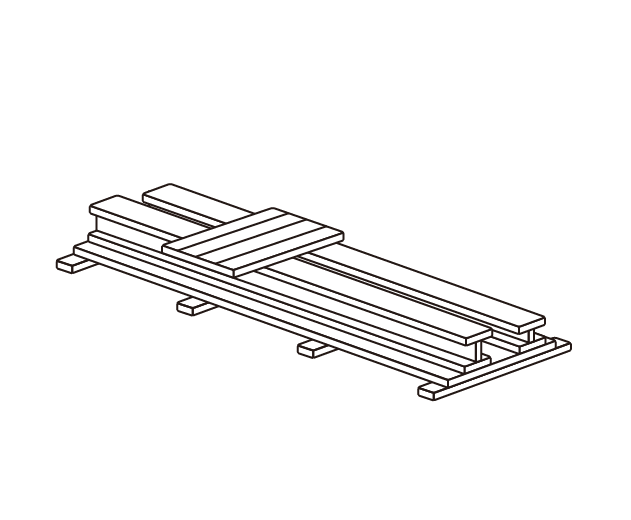

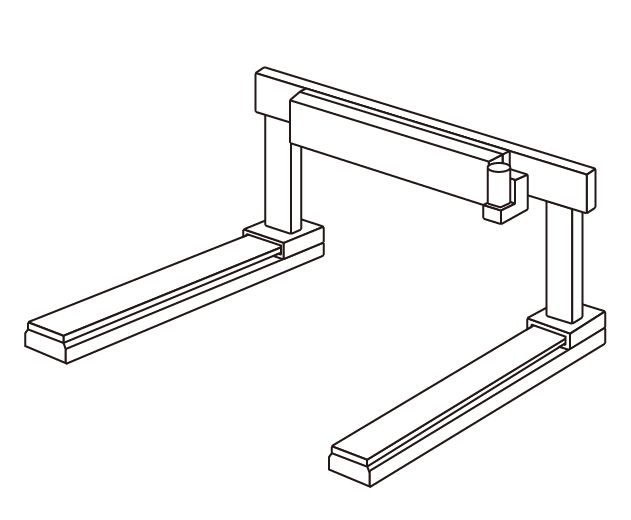

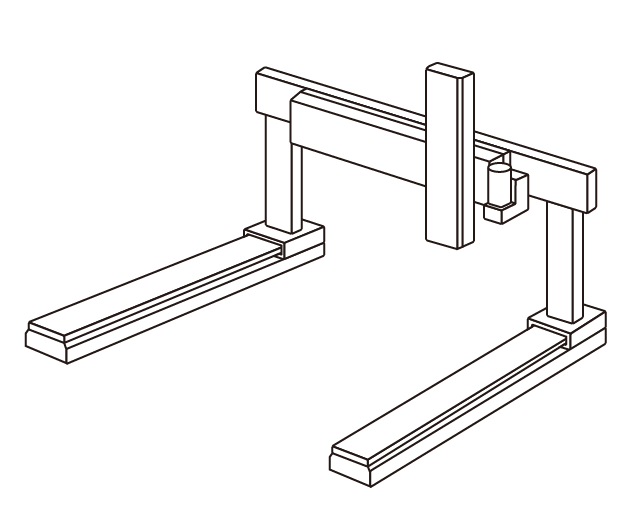

Types of External Axes Supported by NexDroid

Types of Servo Motors Supported by NexDroid

| Brand | Type | Communication Protocol |

| TSINO-DYNATRON | R Series | EtherCAT |

| RC Series | ||

| RD Series | ||

| A8 | ||

| RA Series | ||

| CS Series | ||

| JOTONG | All EtherCAT Models | EtherCAT |

| HANSLASER | All EtherCAT Models | EtherCAT |

| PANASONIC | MADLN05BE | EtherCAT |

| MADLN15BE | ||

| MADLN25BE | ||

| MADLN55BE | ||

| MEDLN83BE | ||

| MCDHT3520BA1 | ||

| MDDHT3530BA1 | ||

| MADHT1507BA1 | ||

| MADHT1505BA1 | ||

| STEP ELECTRIC | AS260_1 | EtherCAT |

| AS260_3 | ||

| AS260_4 | ||

| ZEROERR | eRob70F | Canopen、EtherCAT |

| THINKVO | i3DW | EtherCAT |

| i3DS | ||

| CADMM | ASD6_3 | EtherCAT |

| ASD6_4 | ||

| EYOU | proServo-Planet | Canopen |

| proServo-Harmonic | Canopen、EtherCAT | |

| HCFA | X3E | EtherCAT |

| A2 | ||

| ESTUN | All EtherCAT Models | EtherCAT |

| EURADRIVES | Dual-Axis | EtherCAT |

| SERVOTRONIX | All EtherCAT Models | EtherCAT |

| TECO | JSDG2 | EtherCAT |

| JSDG2S | ||

| MAXSINE | EP3 | EtherCAT |

| EP3E_6 | ||

| ADTECHCN | QXE | EtherCAT |

| DELTA | ASDA_A2 | EtherCAT |

| RUKING | All EtherCAT Models | EtherCAT |

| YANKONG | All EtherCAT Models | EtherCAT |

| INVT | DA200 | EtherCAT |

| EMP | All EtherCAT Models | EtherCAT |

| XINJE | DS5 | EtherCAT |

| ASAGE | All EtherCAT Models | EtherCAT |

| KAISERDRIVE | All EtherCAT Models | EtherCAT |

| SANYO | All EtherCAT Models | EtherCAT |

| PRECISEROBOT | WA | EtherCAT |

| TE CONNECTIVITY | All EtherCAT Models | EtherCAT |

| DORNA | All EtherCAT Models | EtherCAT |

| INOVANCE | IS620 | EtherCAT |

| SV630 | ||

| SV680 | ||

| VMMORE | 300N Series | EtherCAT |

| YAMAHA | All EtherCAT Models | EtherCAT |

| DEALOUR | All Canopen、EtherCAT Models | Canopen、EtherCAT |

| SINEE | All EtherCAT Models | EtherCAT |

| HC-SYSYTEM | ESTS Series | EtherCAT |

| SEVODE | ASD625B | EtherCAT |

| PeitianRobot | PeiTian_115 | EtherCAT |

| PeiTian_125 | EtherCAT | |

| PeiTian_X5_7 | EtherCAT | |

| HCFA | HCFA_X6B | EtherCAT |

| HCFA_Y7 | EtherCAT | |

| HCFA_Y7B | EtherCAT | |

| HCFA_X5B | EtherCAT | |

| HCFA_X3E | EtherCAT | |

| QingChuan | QingChuan_M1 | EtherCAT |

| DVS | DVS EtherCAT type | EtherCAT |

| ELESY | ELESY_ES2 | EtherCAT |

| TIANTAI | TianTai | EtherCAT |

| LEISAI | Leisai | EtherCAT |

| Yaskawa | Yaskawa EtherCAT type | EtherCAT |

| VEINAR | WeiNa_600B6 | |

| Raynen | RA1E | |

| RA3E | ||

| Mt-drive | MT_M800 | |

| MT_M820 |