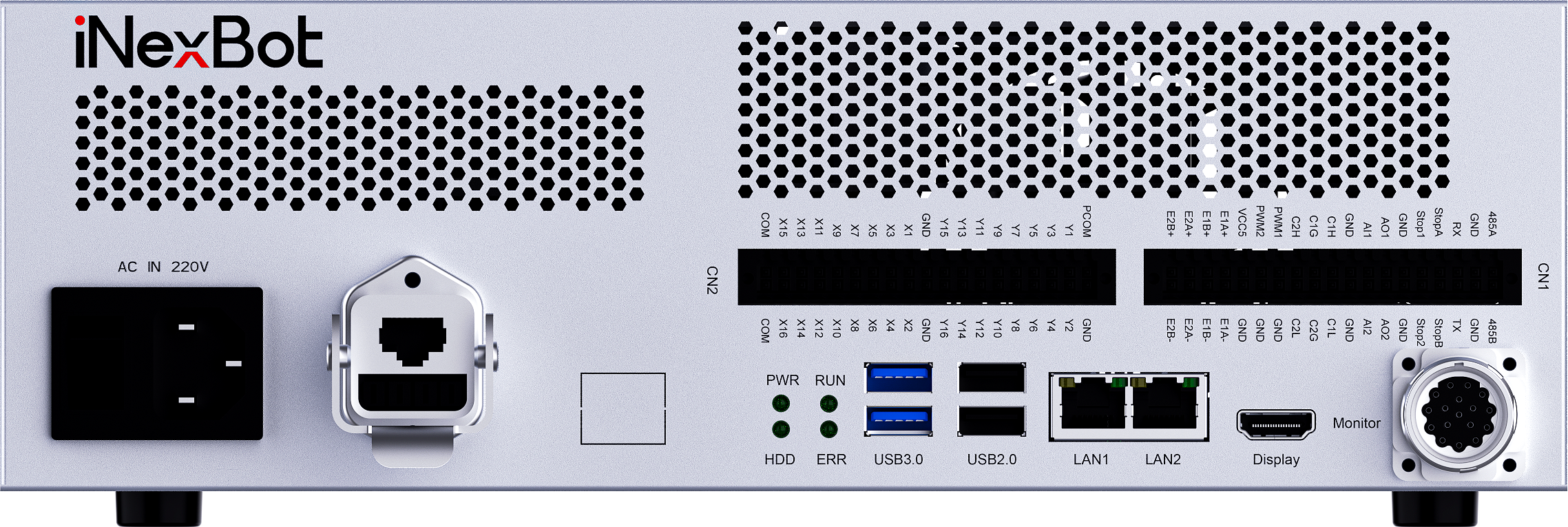

X01 Collaborative Robot Cabinet

Product Introduction

Compact and Powerful, X01 is a dedicated controller for collaborative robots. It adopts self-developed control algorithms and dynamics algorithms, with features such as dynamics-based drag teaching, collision detection, and dynamic feedforward, enabling smooth and flexible drag teaching, as well as trajectory recording and playback.

It comes with a variety of general processes such as loading and unloading, sorting, palletizing, spraying, dispensing, vision, conveyor tracking, and can be customized according to user needs. It also provides a comprehensive API interface - NexDroid API, allowing users to develop their own process algorithms and interfaces in a completely independent and controlled manner.

Please refer to the Open Platform NexDroid for related documents

Features

Small size,Optimized space and Easy operation.

Free to use, Convenient and Efficient.

Highly integrated, Safe and Reliable.

Great Performance with a Friendly price.

Advantages

Dynamics technology

iNexBot's on-load dynamics technology enhances the drag smoothness of robots in loaded scenarios and improves collision detection sensitivity without the need for sensors. With the assistance of dynamic feedforward, it effectively suppresses the vibrations during the operation of heavily loaded robots and the vibrations in loaded conditions.

iNexBot's dynamics identification process is fully automated. After ensuring the safety of the testing trajectory, the dynamic parameters can be identified through the robot's automatic execution of the predefined trajectory, without the need for manual calculations.

Click to view the original video

Drag teaching and trajectory playback

The system supports Dynamics-based drag teaching, allowing for trajectory recording and playback.

Click to view the original video

Built-in general processes

The system is equipped with various general processes such as loading and unloading, sorting, palletizing, spraying, dispensing, vision, conveyor tracking, and can be customized according to user needs. By utilizing the built-in general process functions, users can easily and quickly implement the desired process.

High precision

With the support of robot body accuracy, the NRC series control system can achieve a trajectory accuracy of within ±0.4mm and a repeat positioning accuracy of within ±0.02mm.

Product Parameters

| Product | Parameters |

|---|---|

| CPU | Intel® Celeron J6412, 2.6 GHz |

| Storage | 4G |

| Power Input | 220V 10A |

| Power Output | 48V |

| Power Consumption | 1500W/2000W(Optional) |

| System | Linux RT |

| Port | 1*EtherCAT, 3*Ethernet |

| USB | 2*USB 3.0 |

| COM | 1*RS232, 1*RS485, Isolated |

| I/O | 16*Isolated DI,16*Isolated DO,2AI(0-10V),2AO(0-10V) |

| CAN | 2*CAN |

| Indicator | 1 x PowerLED,1 x HDDLED、1 x RUNLED、1 x ERR LED |

| Display | 1 x HDMI,resolution to 4096x2160@30Hz |

| Installation | Desk-Mount |

| Size | , 307mmx297.20mmx96.20mm |

| Encoder | A、B Phase differential input, 5V supply output;32 bytes Symbol Count, 2 Channel |

| PWM | 2 Channel output, Single Port, Duty Ratio: 0-100%;Voltage: 5V or 24V, Frequency<1MHz |

| WIFI | 2.4G wifi Module(Optional) |

| Teach Pendant | T30 -X Teach Pendant for Cobot: 8 inches TFT (Optional),Linux+QT |

| Comm Protocol | EtherCAT、Profinet、Ethernet/IP、CAN、OPC-UA、FinsTCP、TCP/IP、ModbusTCP、ModbusRTU |

| Coord | Joint Frame、Robot Frame、Tool Frame、User Frame |

| Structure Algorithm | 5/6/7-axis Cobot |

| Application | Arc Welding、TIG、Laser Welding、Point Welding、Punch、Loading and Unloading、Laser Cutting、Spraying、Dispensing、Palletizing、Conveyor tracking, etc |

| Operation Temperature | 0℃ ~ 50℃(SSD) |

| Storage Temperature | -40~85℃ |

| Humidity | 5% ~ 95%, Non-condensing |

| Viberation | SSD: 5~500Hz, 1.5Grms operation |

| Mechanism Shock | Operation:10G@11ms Non-operation: 30G@11ms |

| Weight | 6.92Kg |